Water Cooled Technology

The EMAX Hydro Water Cooled Air Compressor is a groundbreaking innovation in compressed air technology. With new cutting-edge design and tech forward advanced features, it’s pushing the boundaries of what’s possible in air compression. At EMAX, our mission is to eliminate extreme noise and energy waste associated with compressed air systems in the workplace. We do this by providing tech-forward, high-efficiency air systems that not only reduce energy consumption but also minimize noise pollution in the workplace.

Innovative

Cooling Technology

Our Hydro Water Cooled Air Compressor series features four industry-leading patented and patent pending technologies:: Silent Air, Smart Air, Hydro water cooled pump with 100% duty cycle and our easy to use advanced Maintenance Systems. These technologies work together to provide unparalleled energy efficiency, noise reduction, and reliability to significantly reduce or eliminate noise fatigue, operating costs and down time in the workplace.

Quiet, Safe, and Efficient.

Experience the future of air compression technology with the EMAX Hydro Silent Air Compressor. Join the growing number of satisfied customers who have upgraded to EMAX for a quieter, safer, and more efficient workplace.

01 Lowering Maintenance Cost

Hydro Water Cooled compressors significantly reduces maintenance cost over a rotary screw air compressor. Service is low cost – simple and made easy. Keeping your filters and oil changed is all that’s needed. Saving hundreds and even thousands over a rotary type compressor.

02 Energy Savings

Reducing Energy waste is a major goal at EMAX. As reported by a Dept of Energy Study, over 10% of all kilowatts consumed by businesses in the United States is attributed to an air compressor. Hydro Water Cooled automatic on demand sensors yield up to 60% in energy savings during continuous run “compression” mode or 90% in unloading mode.

03 Reduces Contamination

The low-profile Silent Air noise cancellation system not only makes the compressor quieter but also adds four levels of air filtration, providing 250% cleaner air than traditional single-stage air filters that eliminates foreign matter in your applications.

Smart Air Technology

Hydro Water Cooled Air Compressors feature built in Smart Air technology, that provides remote monitoring and control, allowing you to optimize energy savings and maintenance schedules. Our Smart Air integrated technology is also Wi-Fi and Network enabled. for 24-7 monitoring and remote operating control, making it easy to manage your air compression system remotely from any distance.

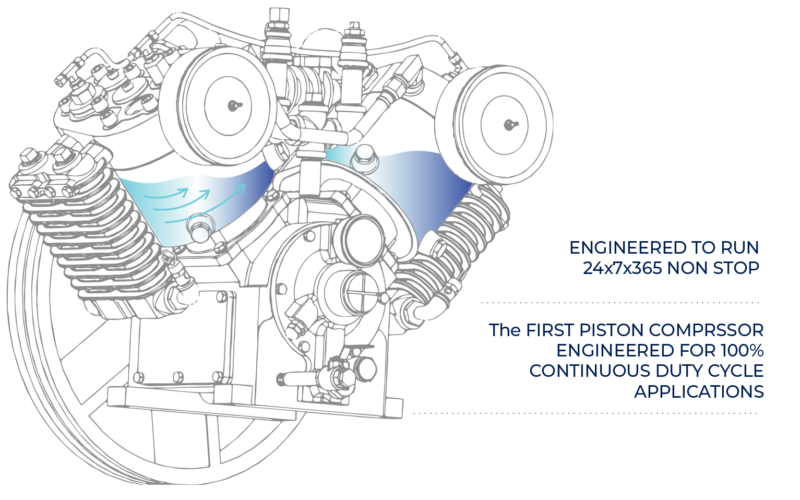

100% DUTY CYCLE

ALL GEN2 EMAX SMART AIR™ compressed air systems feature our HYDRO water cooled pump technology, empowering customers to operate indiscriminately on Single or 3 Phase electric. The first reciprocating (piston) compressor engineered to operate 7x24x365 days a year continuously.

COLD ENVIRONMENTS

The HYDRO water cooled pump design allows for water to reach every crevasse of the pump head assembly to absorb the heat. With a combination of antifreeze and water, the HYDRO Compressor in an outdoor shelter without concerns for pump or head damage in a cold operating environment.

NOISE REDUCTION

EMAX SILENT AIR™ Technology (standard equipped with the HYDRO series) takes sound reduction to an all time low. How? Water circulating in the new HYDRO Water cooled pump acts a noise barrier within the pump reducing operating noise an additional 20%! This is the newest generation of our patented SILENT AIR pump technology & the quietest EMAX Piston Compressor produced in the past 50 Years.

AFTERCOOLER

HYDRO compressed air systems are also equipped with After Coolers using a Split Bar Radiator. The radiator’s dual function reduces the pump water temperature & assists in cooling the air coming out of the pump. The air produced from the pump is within 5 degrees of the surrounding air temperature. With this radiator combination, moisture is also reduced by 50%, even without a dryer. The life cycle of a HYDRO unit is 80,000 hours with recommended regular maintenance at every 1000 hours. The new EMAX HYDRO series, boasts all of the features and benefits of a Rotary Screw compressor with up to 70% lower maintenance & service time at a fraction of the cost plus up to 90% start up Energy

Savings!

Minimizes Maintenance Costs & Downtime

EMAX Maintenance Systems include an industry-leading extended lifetime pump warranty on all pressure lubricated piston pumps. Automatic electronic tank drain systems and integrated refrigerated air dryers with built-in pre-filters and coalescent filtration ensure that your air compression system operates at peak performance. EMAX Smart air support enables technicians to see, diagnose and correctly service issues remotely, to further minimize downtimes.